Karawal Nagar, Delhi

- GST NO. : 07AATFG9932E1ZY

View Mobile Number

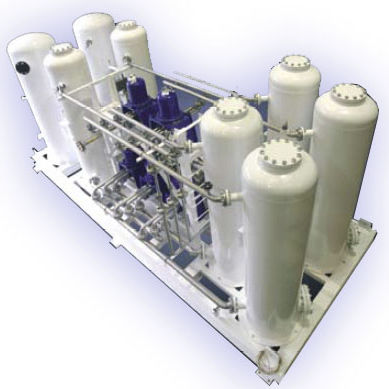

Industrial Gas Plants

Leading Manufacturers, Exporters, Wholesaler and Distributor of Psa Hydrogen Plant, Psa Nitrogen Gas Generators, PSA Oxygen Gas Generator and PSA Oxygen Plants from Delhi.

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Warranty | 1year |

| Brand Name | Kaspo |

| Condition | NEW |

| Application | INDUSTRIAL |

| Certification | ISO |

| Voltage | 440 |

| Type | AUTOMATIC |

| Capacity | 5-60 NM3/HR |

| Product Code | H2 |

| Port | JNPT /Benapole/ ALL OVER INDIA |

| Payment Terms | L/C, T/T |

| Delivery Time | 4 MONTHS |

| Business Type | Manufacturer, Exporter, Supplier |

| Condition | New |

| Color | Light Green |

| Driven Type | Pneumatic |

| Material | CS/SS |

| Brand/Make | GS ENGINEERING/KASPO ENGINEERING |

| Brand Name | Kaspo |

| Capacity | 1-1000 NM3/HR |

| Warranty | 1year |

| Product Code | PSA N2 |

| Port | JNPT /Benapole/ ALL OVER INDIA |

| Payment Terms | L/C, T/T |

| Delivery Time | 1 MONTH |

| Packaging Details | SUITABLE PACKING |

The technology of air-to-nitrogen generation with the use of adsorption processes in PSA Nitrogen generators is well-studied and widely applied at industrial facilities for the recovery of high-purity nitrogen. This is then used in many industries. PSA Nitrogen generators for these industrial applications are designed to produce high-purity nitrogen by regulating gas adsorption and adsorbent (Carbon Molecular Sieves) regeneration by changing pressures in two adsorber-adsorbent-containing vessels. This process requires a constant temperature, close to ambient. The pressure swing adsorption process in each of the two adsorbers consists of two stages running at intervals of a few seconds.

At the adsorption stage oxygen, moisture, and carbon dioxide molecules diffuse into the pore structure of the adsorbent whilst the nitrogen molecules are allowed to travel through the adsorber–adsorbent-containing vessel to be delivered as high-purity nitrogen. To produce high-purity N2, three processes can be used.

Directly with the PSA plant: We can achieve up to 99.9% pure nitrogen directly from the PSA Nitrogen plant. But for larger quantities, this is not economical.

De-OXO System: In industry palladium, de-oxo units are used for nitrogen purity up to 99.999%. In this system, 99% pure N2 from the PSAsystem is mixed with H2 fed in a de-oxo tower filled with a palladium catalyst and the following exothermic reaction takes place O2+2H2 ---2H2O

Copper De-oxo System: This type of de-oxo unit required two externally heated tower-filled copper catalysts. for an endothermic reaction. O2+2Cu---2CuO

The copper catalyst bed can be regenerated by adding hydrogen during the regeneration step. for these 2 step processes i.e DE oxidation and regeneration, two towers are necessary to achieve a continuously operating de-oxo system. The nitrogen from the PSAplant with remaining oxygen passes one of the towers without adding hydrogen. On passing through the tower, the oxygen is removed by reacting with copper and copper oxide form. The advantage of a copper de-oxo unit is that the high-purity nitrogen leaves the unit dry and without any hydrogen. In both types of De-oxo plants, hydrogen gas is required for the removal of oxygen in the De-oxo system with a palladium catalyst and for the regeneration of copper catalyst in the copper de-oxo system. Hydrogen gas can be arranged in a hydrogen gas cylinder or ammonia cracker base hydrogen generation plant. It can also arranged by water electrolysis type hydrogen plant.

| Business Type | Manufacturer, Exporter, Supplier |

| Warranty | 1 Year |

| Warrenty | 1year |

| Usage/Application | Industrial |

| Business Type | Manufacturer, Exporter, Supplier |

| Voltage | 440V |

| Purity | 93% |

| Certification | ISO 9001:2008 |

| Power | AS PER PLANT CAPACITY |

| Automatic Grade | Automatic |

| Warranty | 1year |

| Application | Industrial |

| Brand Name | Kaspo |

| Driven Type | Electric |

| Type Of Compressor | SCREW |

| Color | Light White |

| Design | ASME SEC VIII |

| Capacity | AS PER REQUIREMENT |

| Type | Psa Oxygen Gas Plant |

| Weight | AS PER PLANT CAPACITY |

| Mounting | FLOOR MOUNTING |

| After-Sales Service Provided | YES |

| Country of Origin | India |

| Operating Pressure | 7 BAR |

| Technology Used | PSA |

| Filtration Stages | 4 |

| Purity Of Oxygen | 93 |

| No. of Air Receiver | 1 |

| No. of Storage Tank / Buffer Tank | 1 |

| Air Compressor (kW) | AS PER PLANT CAPACITY |

| Type of Dryer | REF |

| Space Required (L*B*H) | AS PER PLANT CAPACITY |

| Flow Rate(LPM)/(Nm3/hr) | AS PER PLANT CAPACITY |

| Payment Terms | L/C, D/A, D/P, T/T, Other |

PSA Oxygen Gas Plants separates oxygen from compressed air utilizing pressure swing adsorption technology. Compressed Air, which consists of approximately 21% oxygen and 78% nitrogen, is passed through a bed of zeolite molecular sieve. The sieve preferentially adsorbs N2 and moisture allowing the O2 to pass through as a product gas at pressure. While one of the towers is in the adsorption phase the other tower is regenerated by de-pressurizing, at which time the sieve releases the adsorbed gases to the atmosphere, and the cycle is then repeated. Before feeding the air to the PSA tower refrigerated type air dryer and set of filters are installed to cool the air and remove moisture and dust particles.